Science > Physics > Friction > Applications of Friction

In this article, we shall understand why does kinetic friction is smaller than the static friction and why it is easier to roll than solid. We shall also study some everyday examples in which friction is used.

To produce relative motion between two bodies in contact with each other we have to apply a larger force, but once the sliding motion begins a smaller force is sufficient to keep one body sliding over the other. This shows that kinetic friction is smaller than the static friction.

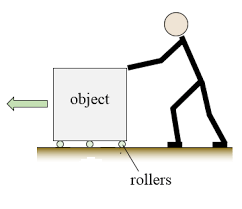

If instead of sliding one body rolls over the other, a very small force is required to maintain the rolling motion. This shows that rolling friction is smaller than the kinetic friction. Hence the order of magnitudes is as follows. Static friction > kinetic friction > Rolling friction

It is Easy to Roll than to Slide:

The origin of the frictional force between two surfaces in contact is due to cold welded joints between the two surfaces at few points on the surface.

To create relative motion additional force is required to break these cold welded joints. This additional force explains the origin of friction and is called a force of friction.

When we are sliding the surfaces one over the other we are shearing the cold welded joints, while when we are rolling the surfaces one over other we are peeling the joints.

During sliding all cold welded joints of the surface should be broken at a time (shearing). While in rolling one line of cold-welded joints is to be broken at a time (peeling). Thus In the process of sheering more force is required than the process of peeling. which clearly indicates that it is always easy to roll than to slide.

Static friction is Greater Than Kinetic Friction:

The origin of the frictional force between two surfaces in contact is due to cold welded joints between the two surfaces at few points on the surface.

To create relative motion additional force is required to break these cold welded joints. This additional force explains the origin of friction and is called a force of friction.

During static friction the surfaces are at rest with respect to each other hence the cold welded joints are stabilised and are strong.

During kinetic friction the surfaces are in relative motion with respect to each other thus the cold welded joints are formed at one instant and broken at the other instant without giving any chance for stabilisation of the cold welded joints. Thus theses bonds are weak. Hence more force is required to overcome static friction than that required in case of kinetic friction. Hence Static friction is greater than kinetic friction

Tyres of Vehicles are Provided With Threads:

The frictional force between the two surfaces depends upon the nature of the surfaces in contact.

The threads of the tyres help to increase friction between the tyre and road.

Due to this, the tyre can get a firm grip on the road and there is no danger of the car running off the road. Hence the tyres of the motor car are provided with threads.

Moving Parts of Machine are Kept Well Oiled:

When energy is supplied to the machine some energy is utilised to overcome the frictional force between the moving parts of the machine. Thus the efficiency of the machine reduces.

The frictional force between the two surfaces depends upon the nature of the surfaces in contact. It also depends on the lubrication between the two surfaces.

The presence of the oil as a lubricant between the two surfaces prevents direct contact between them. It also prevents interlocking of hills and dales on the surfaces of contact. Due to which the friction between the parts of the machine is reduced and the efficiency of machine increases. Hence, The moving parts of the machine are kept well oiled.

Wheels of a Vehicle are Provided with Ball Bearing:

If ball bearing is not used then the force of friction between two parts of the wheel will be that of sliding. This sliding friction is considerable and it causes a significant loss of energy.

If ball bearings are used; the sliding friction is converted into rolling friction, and rolling friction is very small compared to the sliding friction and hence it causes of smaller loss of energy. Hence the wheels of a vehicle are provided with ball bearing to reduce frictional force.

Bearings Used in a Machine are Made of a Different Material:

If two bodies of the same material are in contact with each other; their surfaces in contact have smaller irregularities and therefore the get firmly interlocked. Also, the intermolecular forces of attraction between the two surfaces of the same material are strong. Therefore the friction between the bodies is large.

On the other hand; if two bodies in contact are of different materials; their surface irregularities are dissimilar and hence they cannot get firmly interlocked. Also, intermolecular forces are not very strong hence friction between the bodies is not so large. Hence the bearings used in a machine are made of a different material.

Previous Topic: The Concept of Friction

For More Topic in Physics Click Here