Biology > Microbes in Human Welfare > Sewage Treatment and Biogas

Microbes are used for sewage treatment and biogas production.

Microbes in Sewage Treatment

Necessity of Sewage treatment:

A large quantity of wastewater is generated every day in cities and towns. A major component of this wastewater is human excreta. This municipal waste-water is also called sewage. Sewage contains 99 to 99.5 % water and 0.5 to 1.2 % solids in the form of microscopic particles, colloids, and organic compounds. It contains bacteria like coliforms, streptococci, anaerobic spore-forming bacilli and bacteria from the human intestinal tract. It contains large amounts of organic matter and microbes. Many of which are pathogenic. It cannot be discharged into natural water bodies like rivers and streams directly. Hence, sewage is treated in sewage treatment plants (STPs) to make it less polluting.

Sewage treatment is the process of removing contaminants from wastewater primarily from household sewage. Sewage can be treated close to where the sewage is created, then the system is called a “decentralized” system or “on-site” system. When sewage is collected and transported by a network of pipes and pump stations to a municipal treatment plant, it is called a “centralized” system. Before disposal, sewage treated in sewage treatment plants (STPs). It is done in three stages.

Primary Treatment:

Fat and grease are also removed before the primary treatment of sewage. This step involves physical removal of particles (large and small) from the sewage through filtration of solids and large objects using bar screens and sedimentation. Initially, floating debris are removed by sequential filtration. Then the grit (soil and small pebbles) are removed by sedimentation. All solids that settle form the primary sludge and the supernatant forms the effluent. The effluent from the primary settling tank is taken for secondary treatment.

Secondary Treatment:

The primary effluent is passed into large aeration tanks where it is constantly agitated mechanically and the air is pumped into it. This helps in vigorous growth of useful aerobic microbes into flocs (mesh-like structures). While growing, these microbes consume the major part of the organic matter in the effluent. This significantly reduces the BOD (biochemical oxygen demand) of the effluent. BOD refers to the amount of the oxygen that would be consumed if all the organic matter in one liter of water were oxidized by bacteria. A high value of BOD indicates the presence of more organic matter in the sewage. More the organic matter, more is the polluting potential of sewage. The sewage water is treated till the BOD is reduced.

Tertiary Treatment:

Once the BOD of sewage or wastewater is reduced significantly, the effluent is then passed into a settling tank where the bacterial ‘flocs’ are allowed to sediment. This sediment is called activated sludge. A small part of the activated sludge is pumped back into the aeration tank to serve as the inoculum. The remaining major part of the sludge is pumped into large tanks called anaerobic sludge digesters. Here, other kinds of bacteria, which grow anaerobically, digest the bacteria and the fungi in the sludge. During this digestion, bacteria produce a mixture of gases such as methane, hydrogen sulphide and carbon dioxide. These gases form biogas and can be used as the source of energy as it is inflammable.

Discharge:

The effluent from the tertiary treatment plant is generally released into natural water bodies like rivers and streams. The Ministry of Environment and Forests of India has initiated the Ganga Action Plan and Yamuna Action Plan to save these major rivers of our country from pollution. Under these plans, it is proposed to build a large number of sewage treatment plants so that only treated sewage may be discharged into the rivers.

Biogas:

Biogas is a mixture of gases (containing predominantly methane) produced by the microbial activity and which may be used as fuel. It is a non-conventional and renewable source of energy. Biogas production involves anaerobic microorganisms growing in marshy places, organic sediments, in the rumen of ruminant animals. These bacteria are collectively called methanogens, and one such common bacterium is Methanobacterium. Plant waste and animal waste are used for the production of biogas.

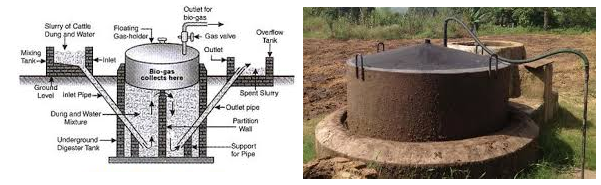

Biogas plant:

Biogas plant consists of a Concrete tank 10- 15 feet deep It is fed through inlet tank by plant waste, animal waste, slurry or dung. A floating metal cover in the form of the dome is placed above the main tank. It rises as biogas content inside the tank increases. A connecting pipe with a valve is provided for the supply of biogas to point of use. Digested sludge can be removed from digesting sludge outlet. Cattle dung is available in large quantities in rural areas where cattle are used for a variety of purposes. So biogas plants are more build in rural areas. The biogas produced is used for cooking and lighting.

Biogas Production Process:

It involves three processes

Anaerobic digestion or hydrolysis: (Polymers → Monomers)

In this process complex, insoluble polymers are converted to simple soluble monomers. Microbes involved are anaerobic bacteria like Clostridium, Pseudomonas

Acetogenesis or Acidogenesis: (Monomers → Organic acids)

In this process monomers formed in the last process are converted into organic acids, mainly acetic acid by acidogenic bacteria. Acidogenic bacteria are anaerobic bacteria.

Methanogenesis: (Organic acids → Methane + CO2 + other gases)

In this process, organic acids are converted into biogas by methanogenic bacteria. Bacteria involved are Methanococcus and Methanobacillus.

Advantages of Biogas:

- It is a cheap, safe and renewable source of energy.

- It can be used for domestic lighting, cooking street lighting and in small-scale industries.

- It burns with a blue flame without smoke.

- It does not cause pollution or imbalance in the environment.

- It can be easily produced, stored, transported and its control of flame is easy.

- It improves sanitation of the surroundings.

Previous Topic: Industrial Uses of Microbes

Next Topic: Biofertilizers and Biocontrol Agents